Production technique [Shino]

Moment of change

Shino is an elusive vessel that was created for only a brief period in the tea world over 500 years ago.

It was fired for only about 20 to 30 years from the late 16th century to the early 17th century (in large kilns and anagama kilns), but it blossomed during a transformative period in Japanese art, revolutionizing the aesthetic sensibilities of the people at the time.

The charm of Shino lies in its characteristic appearance of a snow-white surface, created by using feldspar, with a subtle, warm fire color visible within it.

Bringing out this beautiful color is extremely difficult due to the need for strong reduction firing, where the kiln temperature does not easily rise, necessitating constant temperature adjustments day and night. The kiln firing lasts for more than seven days, conducted under extremely harsh conditions, requiring careful attention.

The outcome varies significantly with the seasons and climate, demanding a level of delicacy that allows for no moment of inattention.

Shino's colors leave an impression like "the soil seen after the snow melts" or "a beautiful sunset formed by clouds and the setting sun."

Capturing and expressing the fleeting beauty of nature without any preconceived ideas or intentions, Shino continues to captivate people's hearts both now and in the past.

The raw material for Setoguro and Shino,

Mogusa clay,

is a rare clay that is difficult to obtain,

destined to become the material for elusive vessels.

The clay found in the Mino region is considered rare even on a global scale.

Over thousands of years, volcanic activity and rain have altered its properties. The natural terrain, surrounded by mountains, has produced the unique clay specific to this region. The soil accumulated in this area, commonly known as Mogusa clay, contains a small amount of iron and can withstand rapid cooling. This results in the deep, absorbing black of Setoguro and the beautiful fiery red that symbolizes Shino. Mogusa clay is coarse and contains many fine air pockets, giving the finished product a warm and soft feel that fits comfortably in the hand.

100 days of pottery making process

The approximately 100-day pottery process until the completion of the vessel results in a unique creation born from various encounters and experiences.

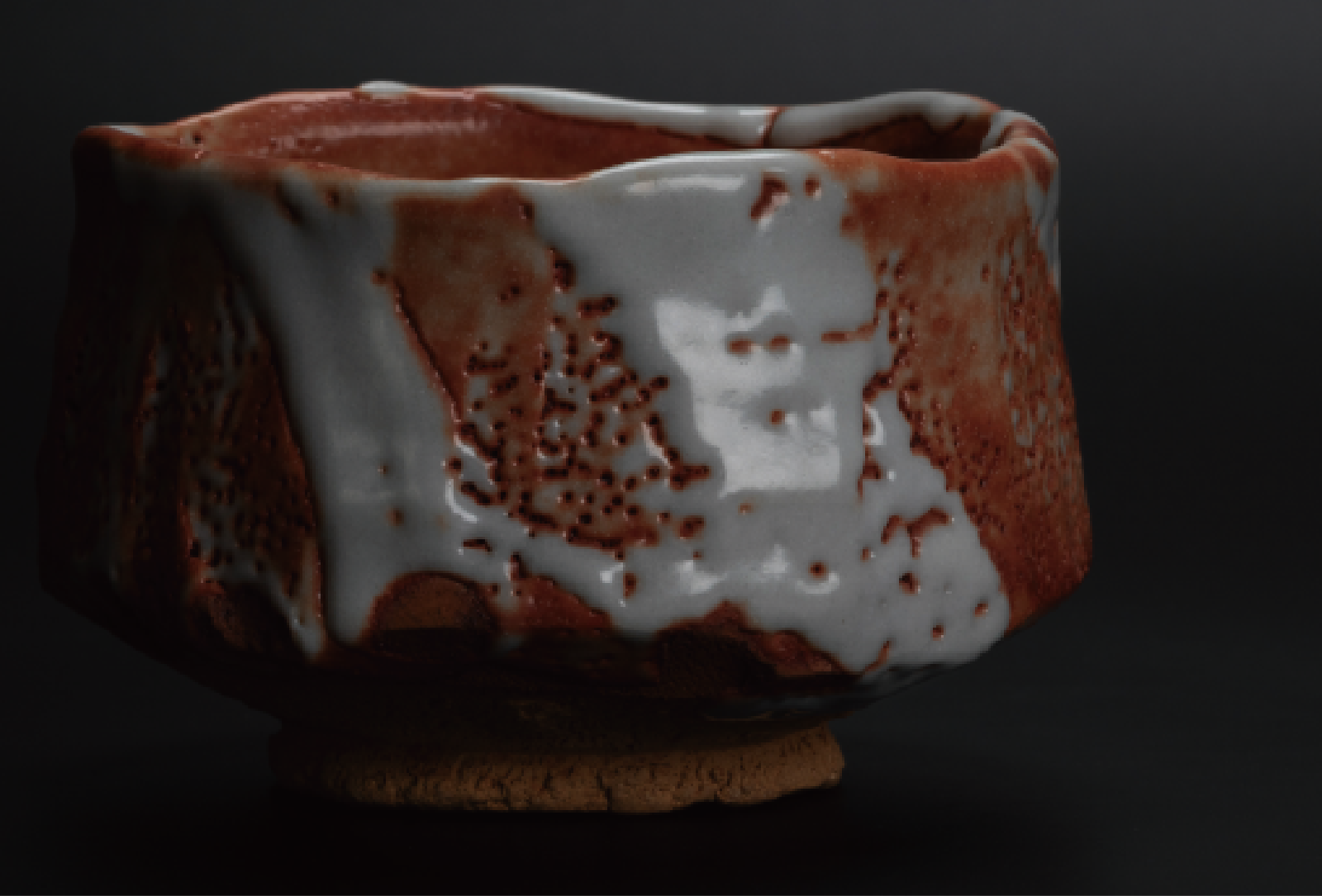

Shino Matcha bowl

Shino Matcha bowl

The charm of Shino lies in its snow-white appearance created by using feldspar, with a hint of warm fire color visible within it. It leaves an indescribable impression, like "seeing soil and new buds through melting snow" or "a beautiful sunset through gaps in the clouds." Bringing out this beautiful color is extremely difficult, requiring strong reduction firing where the kiln temperature does not easily rise, necessitating constant temperature adjustments day and night for more than seven days. The firing results vary greatly with the seasons and climate, requiring a level of delicacy that allows for no moment of inattention.

Shino Shunomi

Shino Shunomi

Sake enjoyed with Shino ware is exceptional. Compared to glass, Tokkuri and Guinomi are made from clay, with a coarse texture that allows the vessel to "breathe." This enhances the aroma of the sake and mellows its flavor, leading to the saying, "Sake enjoyed with Shino ware is exceptional." Sake and Shino ware, born in the same era and from the same land. Please savor them while feeling the 500 years of history.

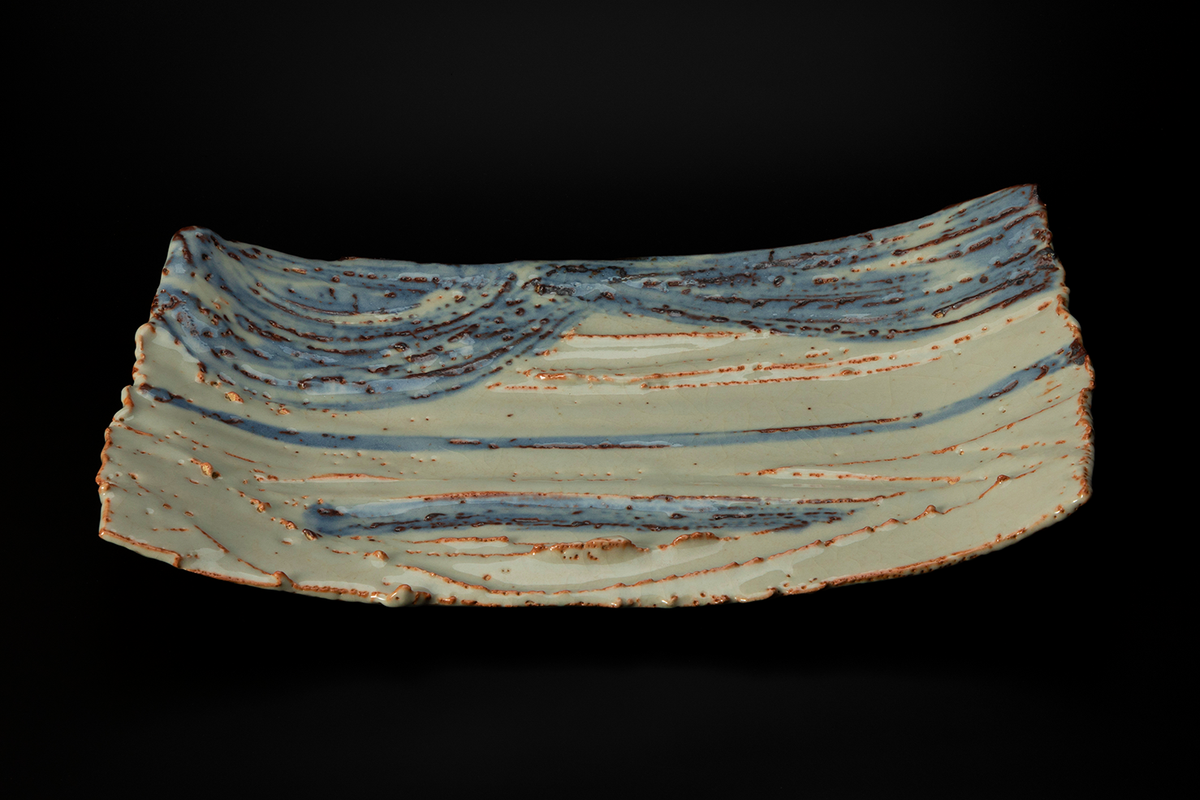

Shino plate

Shino plate

Son's works express the four seasons and nature of Japan. As you enjoy your meal, the character of the vessel emerges. Setoguro and Shino plates not only enhance the dishes but also allow you to feel the beautiful nature of Japan after the meal.

Shino flower vase

Shino flower vase

Shino flower vases are well-suited for wildflowers and branches. Even without arranging flowers, the design of the vase allows you to enjoy the changing seasons and nature, making it delightful to display as is.

Shino Tsubo

Shino Tsubo

Shino Yunomi

Shino Yunomi

Shino yunomi are made from clay with coarse particles, giving the impression that the vessel "breathes."

Additionally, the soft, bulging milky white color, unique to Shino ware, fits comfortably in the hand and feels warm.

By using a Shino yunomi daily, the vessel "grows" and deepens in character over time.

The patina that develops on a Shino yunomi over the years changes its appearance, making it exceptionally flavorful and fostering a sense of attachment.

Because you use it every day, enjoy the experience of nurturing a high-quality, unique vessel that is your very own.

How to use and care for your utensils

Wipe off the water with a soft cloth or kitchen paper.

Sun-dry for 2 hours, or if the weather is bad or drying indoors, dry for 12 hours.

The bottom (foot) of the matcha bowl is where you can directly feel the rare clay, but it can absorb water.

To prevent mold, please complete the drying process as outlined in STEP 3.